Engineering & Research

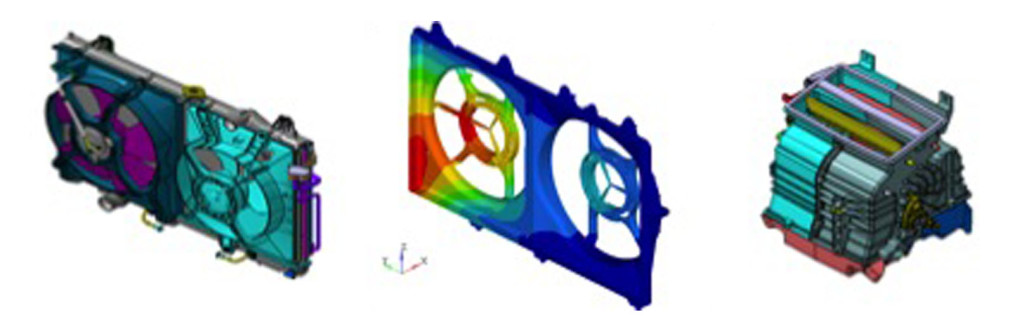

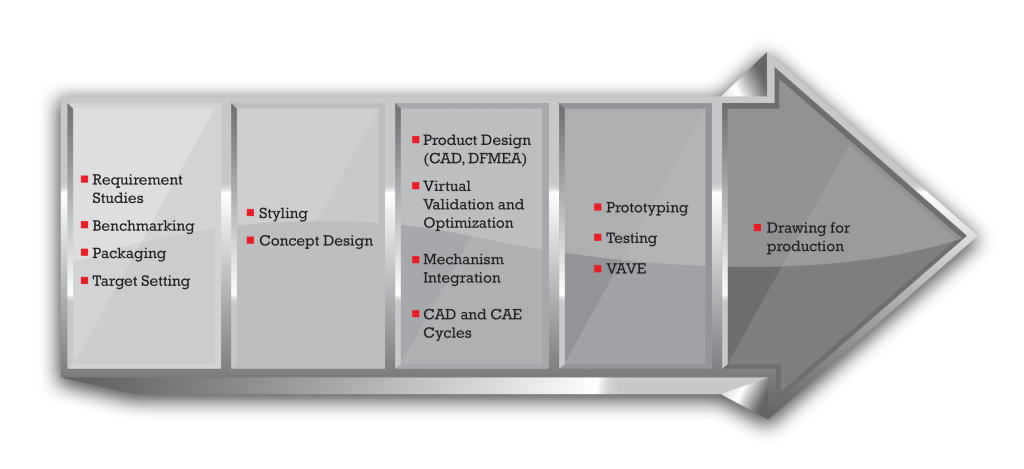

SIMULATION DRIVEN DESIGN

“Simulation has proven to be a time and cost-effective alternative to physical testing - allowing more design options to be considered in shorter time frames. APM is seeking to further expand the use of simulation by bringing it forward even earlier in the design process.

However, the challenges of implementing a simulation-based design strategy include the absence of an engineering environment and process that can keep pace with the design team”.

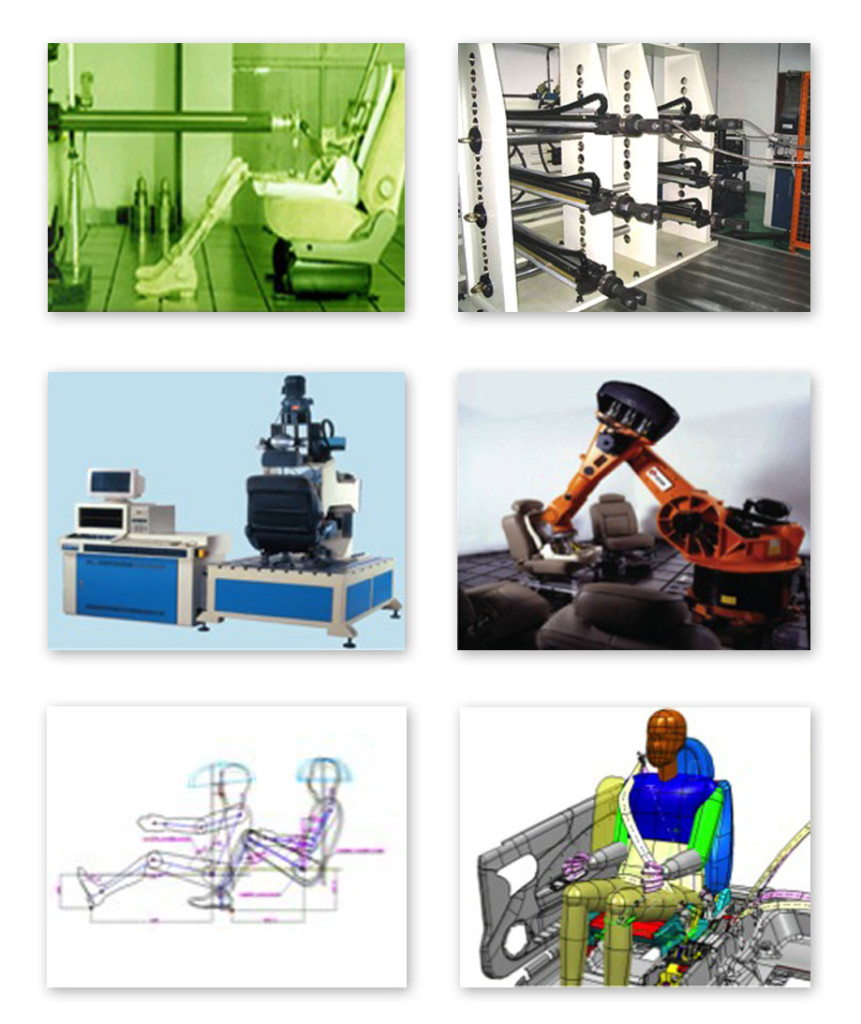

SEATING SYSTEM

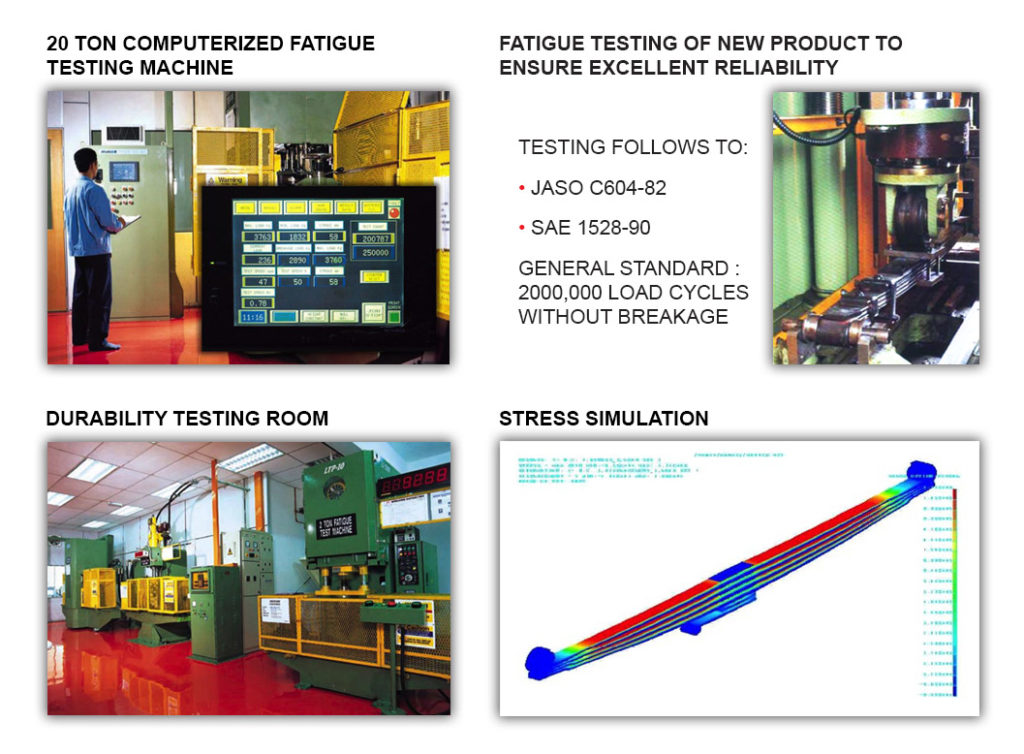

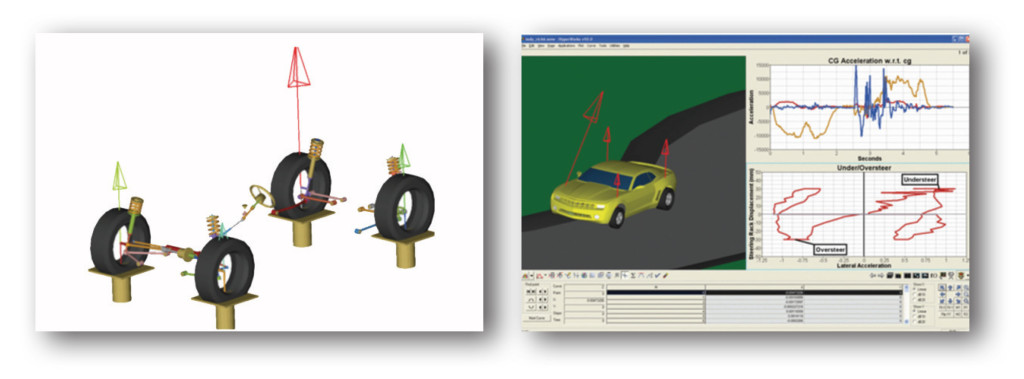

SUSPENSION SYSTEM

CLIMATE CONTROL

INTERIORS & PLASTICS

PASSENGER VEHICLE SUSPENSION TEAM RESEARCH FOCUS

To design and develop best-in-class Safer, Lighter, Eco-Friendly, Durable, Cost Competitive passenger vehicle suspension modules by focusing the research activities in the following areas :

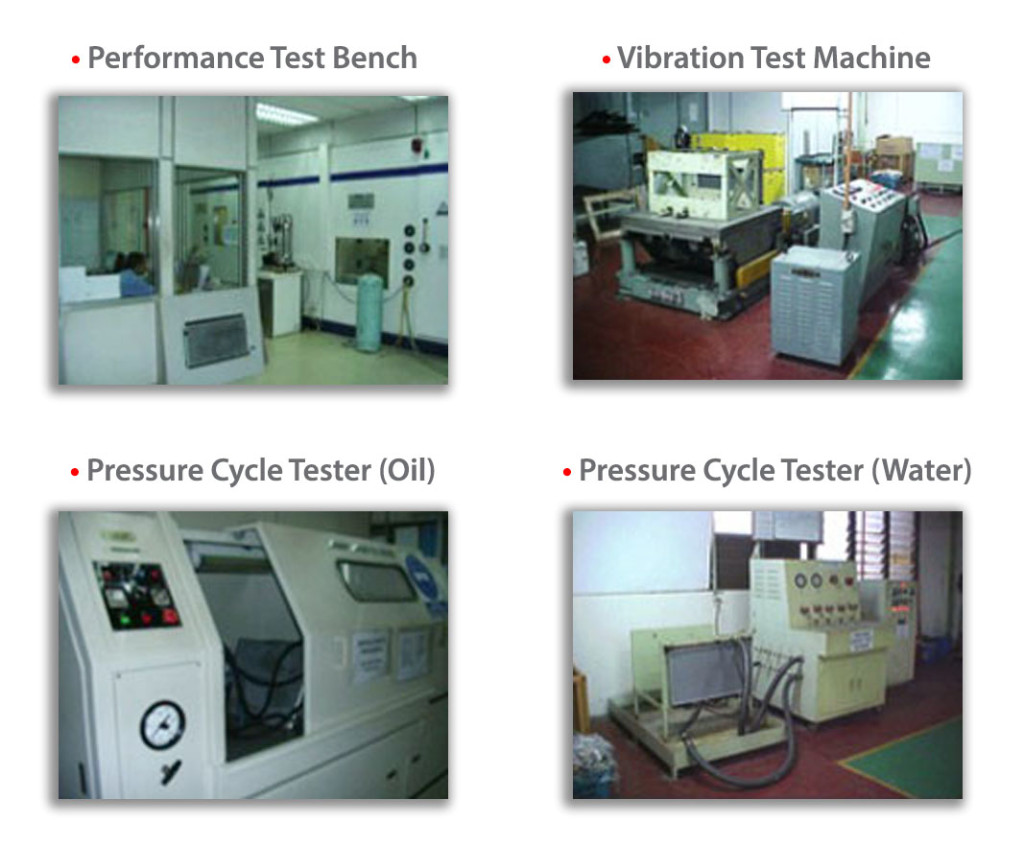

INTERIOR TESTING FACILITIES